In-house Research & Development facility with latest software – Pro Engineer, Tebis etc.

In-house Research & Development facility with latest software – Pro Engineer, Tebis etc.

In-house Pattern manufacturing facilities including LORAMENDI Gripper. All CNC machines networked with CAM

Technical Tie-up with Azterlan, Spain & IIT, Ropar

Siamese Tooling capability helps us in reducing the wastage and increasing productivity

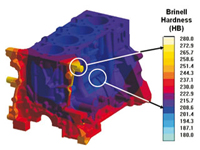

MAGMASOFT® simulation capabilities provide thorough understanding of mould filling, solidification, mechanical properties, thermal stresses and distortions.

Wide range of equipment available for following technologies:-

Wide range of equipment available for following technologies:-

Cold Box

Shell Core

Various washes capability to suit product requirement viz. Graphite, Zircon, Arkopal, Forecoat,CAC wash, Tellurium etc.

| Technology | No. of Machines | Plate Size in mm |

| Cold Box | 21 | 1100x850x400 |

| Hot Box - Shutter | 07 | 1140x890x350 |

| Shell | 35 | 900x900x400 |

| Loramendi | 3 (40 ltr) | 1300x100 |

| Loramendi | 2 (65 ltr) | 1100x900 |

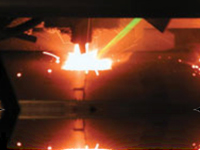

Real Time Vision Based Control System installed for Automatic Pouring of Molten Metal with inoculants feeding & temperature measurement.

Real Time Vision Based Control System installed for Automatic Pouring of Molten Metal with inoculants feeding & temperature measurement.

The vision system as a closed-loop, self-compensating automatic pouring system increases the productivity and reliability of the casting process by eliminating the costly over pours and short pours.

We have installed two Maus Machines to do cylinder block fettling having capacity of 1000 MT approx.

We have installed two Maus Machines to do cylinder block fettling having capacity of 1000 MT approx.

All loramendi blocks are fettled at MAUS machines.

Machining with nearby machining vendors.Supplying machined Heads to Mahindra.Exporting machined Heads to Perkins, UK

Machining with nearby machining vendors.Supplying machined Heads to Mahindra.Exporting machined Heads to Perkins, UK

Developed fully machined Blocks & Heads for Daimler LDT Engine.In-house set-up for doing proof machining of Blocks

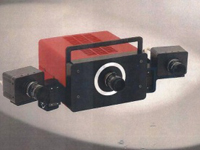

White Light Scanner is a topography system Working with two cameras to correctly & precisely capture 3D topographic of the object under scanning. It is being used for tooling inspection, core & casting inspection, Preventive maintenance of tooling.

White Light Scanner is a topography system Working with two cameras to correctly & precisely capture 3D topographic of the object under scanning. It is being used for tooling inspection, core & casting inspection, Preventive maintenance of tooling.

Lampe Automatic and Loramendi cold box sand mixing & distribution system

Lampe Automatic and Loramendi cold box sand mixing & distribution system

Homogenous core sand mixture ensures consistency in sand properties and reduced gas generation

Exactly reproducible binder dosage ensures appropriate strength of cores resulting in right core hardness and reduced core breakage

Auto Core Cell gives highest level of dimensional accuracies, reduced core breakage and high productivity.

Auto Core Cell gives highest level of dimensional accuracies, reduced core breakage and high productivity.

Assembled cores will be the output of Auto Core Cell resulting in castings with minimal weight variation from the Design weight.

Parting line fins and Mismatch will be minimal thus reducing excessive fettling.

| Furnace | Plant -1 | Plant-2 |

| Type | Medium Frequency | Medium Frequency |

| Make | Herman Line (US) | Kunkel Wagner (German) |

| No. of Furnaces | 3 | 3 |

| Melting Rate MT/hr | 8.0 | 7.8 |

| Auto Pouring (press pour) | 1 Machine | 1 Machine |

| Capacity MT/hr | 8.0 | 7.8 |

| Moulding Line | Herman | Kunkel Wagner |

| Flask Size | 1140x810x406 mm | 900x800x350 mm |

| Moulds / Hour | 50 | 120 |

| Technology | High Pressure Moulidng | High Pressure Moulidng/ Air Press |